Table of Contents

ToggleThe automobile wiring harness runs throughout the entire car. It connects various electrical devices on the car and serves as a medium for the power supply and signal transmission of each device. This article mainly introduces the components and functions of automobile wiring harnesses

1. What is a wiring harness?

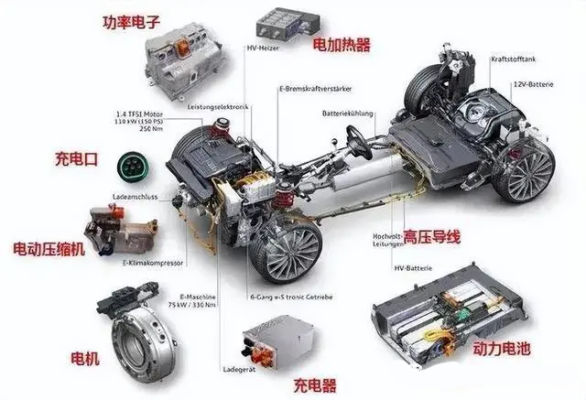

The automobile wiring harness is often compared to the car’s neural network system. The automobile wiring harness is the network main body of the automobile circuit. Without the wiring harness, there would be no automobile circuit. The literal meaning of a wiring harness is a bundle of wires. The automotive wiring harness defines the usage environment of the wiring harness, that is, it is assembled on the car, as shown in the figure below:

Figure: Vehicle wiring harness (red part)

The automobile wiring harness runs throughout the entire car. It connects various electrical devices on the car and serves as a medium for the power supply and signal transmission of each device. The automobile wiring harness is often compared to the car’s neural network system. The automobile wiring harness is the network main body of the automobile circuit. Without the wiring harness, there would be no automobile circuit.

2. Functions and functions of the wiring harness

The wiring harness is an indispensable system-level component in the vehicle. Its function is to provide and distribute power to various systems in the vehicle, and at the same time, it serves as a medium for signal transmission between various components.

Figure: Car’s neural network system

To put it bluntly, if a car’s electrical components, such as headlights, want to be powered by power, they need to be connected to the battery or generator through a wiring harness to form a power loop. For the headlights to light up, the body controller (BCM) must recognize the driver’s intention to turn on the light combination switch. The signal interaction between the combination switch and the BCM also needs to pass through the wiring harness.

3. components of automobile wiring harness

The range of low-voltage wiring harness components is wide, including cables, connectors, terminals, fuse boxes, relays, fuses, plastic brackets, metal brackets, PVC insulation tubes, corrugated tubes, heat shrink tubes, sealing rings, rubber sleeves, tapes, Cable ties, protective covers, bolts, etc.

Figure: Exploded view of low-voltage wiring harness assembly components

Automotive wiring harnesses are composed of wires, connectors, wire harness wrappings, wire harness fixings (buckles, rubber parts, wire harness brackets, etc.), and wire harness accessories.

Figure: Wiring harness assembly-actual object

electric wire

Wires are the main component of the wiring harness, often called wires. They are the main part of the wiring harness and their main function is to carry the current required by the load. The important parameter of a wire is its current-carrying capacity. The current-carrying capacity of a wire is affected by the wire diameter (the cross-sectional area of the wire conductor), the wire length, the resistivity of the conductor, and the ambient temperature.

Figure: Wires

Connector

Connectors are also called connectors, CONNECTOR, or connectors. Connectors are indispensable components for connecting wire harnesses to other electrical equipment. They are divided into wire harness end connectors and electrical appliance end connectors.

We often hear about male connectors (referred to as male terminals) and female connectors (referred to as female terminals). The connector where the male terminal is located is called a male connector, and the connector where the female terminal is located is called a female connector. The ones on our wiring harness end are usually female connectors.

Figure: Connector

For wiring harnesses, connectors are relatively precise parts. To ensure the connection performance between the wiring harness assembly and electrical equipment, male and female connectors are generally required to be used in sets, that is, the same set of connectors from the same manufacturer is selected. This is important for the car. This is very important for parts and safety parts, such as airbags and ABS.

Connectors can be divided into two categories: waterproof and non-waterproof. At the beginning of the design, PIN pins of different widths are selected according to the current that each PIN pin needs to carry, and then a cavity is formed on the connector to accommodate different PIN pins, thereby forming a Housing that accommodates multiple PINs.

Picture: Housing+CPA+Sealing Ring

CPA, plastic shell secondary locking mechanism (ConnectorPositionAssurance). Its function is to ensure that the buckle of the primary locking mechanism will not be easily withdrawn after the plastic shell and electrical interface are assembled in place. Due to its special function, CPA must ensure worker operability and legibility when designing. This is CPA is required to be an independent organization on the plastic shell and must also have a special color mark.

Waterproof sealing ring: There are two types of waterproof sealing mechanisms, one is used for sealing between plastic cases, and the other is used for sealing terminal leads.

TPA, terminal secondary locking structure, TerminalPositionAssurance. Not all terminals require a secondary locking structure. VW requires that TPA should be used when the terminal width is less than 2.8mm (including 2.8). To ensure the convenience of installation by wire harness factory workers, the color of TPA must also be identifiable and must be used during assembly. It has a clear feel. To ensure that the TPA will not automatically enter the locking position when the plastic case is transported to the wiring harness factory, an anti-locking mechanism is necessary on the TPA.

Wire harness wrapping

The main function of wire harness wrapping is to protect the wiring harness. Depending on the material of the wrapping, the main types of wrapping include corrugated pipe, PVC tape, cloth tape, flannel tape, sponge tape, and aluminum foil tape.

Due to different materials, the material properties of different wrappings are also inconsistent. Correspondingly, their application conditions and methods on the wire harness assembly are also inconsistent. The specific selection should be based on the specific use environment of the wire harness and its wear resistance and heat resistance.

Figure: Wiring harness wrapping

4. wire harness fixtures

Unlike other parts on other cars, the wire harness is a flexible part and the wire harness cannot be sent in a predetermined shape. Therefore, to constrain the layout path of the wire harness on the entire vehicle, additional parts need to be added to fix the wire harness. These additional parts The part is the wire harness fixture, which plays the role of fixing the wire harness and constraining the wire harness layout path.

Wire harness fixtures include cable ties, buckles, rubber sheaths, wire harness brackets, etc. Depending on the installation environment of the wire harness, such as the wiring harness installation space, temperature requirements, waterproof requirements, and the shape and shape of each wire harness fixture The materials are not consistent. Even so, the wire harness fixtures also show a trend of standardization, and they are also one of the components that is easier to implement in the selection of wire harness platforms.

Figure: Wiring harness fixing parts

5. wire harness accessories

Wire harness accessories refer to other smaller products on the wire harness assembly, such as product labels, fuse clips, etc. on the wire harness assembly.

0