Table of Contents

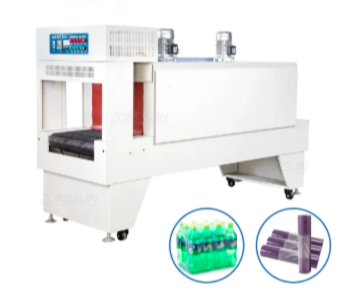

ToggleShrink wrap machines are an essential tool in modern packaging, providing a reliable solution for bundling and protecting products. These machines use heat to shrink plastic film tightly around an item, creating a secure and professional-looking package. This article delves into how shrink wrap machines work, their advantages, and factors to consider when choosing the right machine for your needs.

The Working Principles of Shrink Wrap Machines

Understanding how shrink wrap machines function can help businesses maximize their efficiency and product protection.

1. Material Preparation

1. Material Preparation

Shrink wrap machines use shrinkable plastic films such as polyolefin or PVC. These materials contract when exposed to heat, making them suitable for various applications, from food packaging to industrial goods.

2. Product Loading

The product is placed within the shrink film, either manually or through an automated feeding system. For high-volume operations, conveyor systems ensure seamless product movement into the wrapping zone.

3. Film Sealing

Shrink wrap machines feature sealing mechanisms, such as L-bar or impulse sealers, to cut and seal the film around the product. Advanced machines can seal with precision, ensuring no gaps or loose edges.

4. Heat Application

The product, enclosed in shrink film, passes through a heat tunnel or chamber. Temperatures within the chamber range from 150°C to 200°C, depending on the film type. The heat causes the film to contract, forming a snug fit around the product.

5. Cooling and Quality Check

After shrinking, the package is cooled to solidify the film. Quality control systems inspect for defects such as wrinkles or incomplete seals, ensuring a professional finish.

Advantages of Shrink Wrap Machines

Shrink wrap machines offer numerous benefits that make them indispensable in packaging operations.

1. Product Protection

Shrink wrap provides a barrier against dust, moisture, and tampering. For instance, electronics wrapped in shrink film have a significantly reduced risk of damage during transportation.

2. Versatility

Shrink wrap machines accommodate various product sizes and shapes. From small items like DVDs to large pallets, these machines ensure secure packaging.

3. Efficiency

Automated shrink wrap machines can process up to 100 packages per minute, making them ideal for high-volume production lines.

4. Cost-Effectiveness

Shrink wrapping uses minimal material while delivering robust protection, reducing packaging costs.

5. Enhanced Aesthetics

Shrink wrap creates a clean, transparent finish that enhances product presentation, which is crucial for retail settings.

Key Factors to Consider When Choosing Shrink Wrap Machines

Selecting the right shrink wrap machine is vital for meeting production needs and achieving optimal results.

1. Production Volume

For small-scale operations, a semi-automatic shrink wrap machine may suffice, processing up to 20 packages per minute. Larger facilities should opt for fully automated models capable of handling over 100 packages per minute.

2. Film Type Compatibility

Different shrink films have specific properties. For instance, polyolefin is food-safe and flexible, while PVC is more rigid and suitable for industrial applications. Ensure the machine supports your chosen film type.

3. Machine Size and Layout

Consider the available floor space and the machine’s dimensions. Compact models are ideal for limited spaces, while larger machines are better suited for expansive production lines.

4. Temperature Control

Machines with adjustable heat settings provide greater flexibility for various film types and products, ensuring optimal shrink performance without damaging the product.

5. Maintenance and Durability

Opt for machines made from durable materials like stainless steel and those with accessible components for easy maintenance.

Conclusion

Shrink wrap machines are a cornerstone of efficient and effective packaging, offering unparalleled protection, versatility, and cost-efficiency. By understanding their working principles and benefits, businesses can better appreciate their role in the packaging process. Furthermore, considering factors such as production volume, film compatibility, and machine durability ensures the selection of the right shrink wrap machine, enhancing overall operational success. Whether you’re packaging small consumer goods or large industrial products, shrink wrap machines deliver professional results that meet modern packaging demands.

0