Table of Contents

ToggleThe integration of printed circuit boards is getting higher and higher, and the power of components is getting higher and higher, especially high-power transistors, RF power supplies, LEDs, etc. in the fields of communications, rail transit, automotive electronics, military, photovoltaics, etc. The package form of the device is usually BGA, QFN, CSP, LGA, etc. Its common characteristics are high power consumption and high heat dissipation requirements, and the void rate of the heat dissipation plate directly affects the reliability of the product; for example, the solder joint is affected by the void, and the solder joint The mechanical strength of the solder joints decreases, the thermal resistance increases, and the current path decreases, which will affect the thermal conductivity and electrical conductivity of the solder joints, thereby reducing the reliability of the product. Therefore, you need vacuum reflow ovens and vacuum soldering machines to solve these problems.

What is a Vacuum Soldering Machine?

The vacuum reflow soldering process is a reflow soldering technology that introduces a vacuum environment during the reflow soldering process. Compared with traditional reflow soldering, vacuum reflow soldering is a cavity where the product enters the back end of the reflow soldering area and then enters a vacuum environment. It can be reduced to below 5 bar and kept for a certain period to realize the combination of vacuum and reflow soldering. At this time, the solder joint is still in a molten state, and the external environment of the solder joint is close to a vacuum. Air bubbles in the dots can easily escape from them, which greatly reduces the voiding rate of the solder joints.

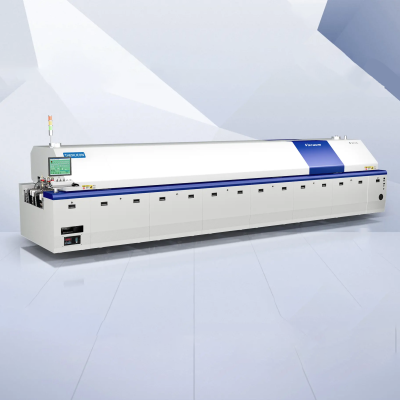

Vacuum reflow ovens ensure cost-effectiveness. An ideal example of a vacuum reflow oven is the TRV Series Vacuum Assisted Reflow Oven. The machine has a wide variety and is specially designed for different products, which can effectively reduce the void rate of the product and improve the reliability of the product. JT vacuum reflow soldering adopts a thick heat storage aluminum plate to ensure a stable temperature in mass production; the entire transmission system is divided into three sections, and the overall width is adjusted independently for transportation. The reliable transmission system ensures efficient production capacity; an efficient flux recovery system prevents Residual rosin. From design to production, JT vacuum-assisted reflow soldering is only for the perfect soldering of products, bringing customers a better experience and improving factory production efficiency.

Conclusion

In summary, the adoption of vacuum reflow ovens and vacuum soldering machines is essential for manufacturers striving to meet the increasing demands of modern electronics. The ability to minimize void rates significantly enhances the reliability and performance of solder joints in high-power applications. By leveraging these advanced technologies, manufacturers can not only improve the quality of their products but also increase overall production efficiency. Investing in vacuum soldering solutions is a strategic choice for those looking to stay competitive in the rapidly evolving electronics market.

0