Table of Contents

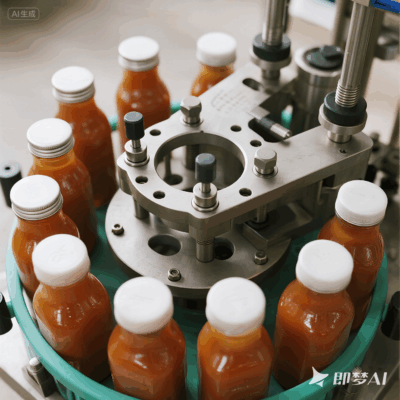

ToggleIn modern production, whether you’re producing beverages, sauces, cosmetics, or cleaning products, a bottle filling and capping machine ensures each bottle is accurately filled and securely sealed, meeting quality standards and consumer expectations.

Understanding how a bottle filling and capping machine works can help businesses select the right equipment, perform proper maintenance, and maximize production efficiency.

1. The Role of a Bottle Filling and Capping Machine in a Production Line

Before delving into the working principles, it’s important to understand why bottle filling and capping machines are so important. In high-volume production, manual filling and capping can lead to inconsistent product quantities, loose caps, and the risk of contamination.

Automated machines address these issues by providing high fill volume accuracy, consistent cap sealing torque, reduced labor costs, and increased production speeds.

By combining filling and capping into a continuous process, these machines improve efficiency and reduce downtime between stages.

2. Bottle Filling and Capping Machine Production Line

1) Bottle Feeding Process of a Bottle Filling and Capping Machine

The working principle begins with bottle feeding. Empty bottles are transported to the bottle filling and capping machine via a conveyor. In fully automated systems, a bottle unscrambler or feeder aligns the bottles in the correct orientation before they enter the machine.

- Manual systems may require an operator to place the bottles on the conveyor.

- Automated systems use sensors to detect the presence of bottles and prevent blockages.

- This stage ensures a smooth and continuous flow of bottles into the filling section, without damage or misalignment.

2) Filling Process in the Bottle Filling and Capping Machine

Bottles for different products are filled using different filling methods: Piston filling, suitable for thicker products like sauces and creams, uses a piston to push a precise amount of material into the bottle.

- Pump filling, using a pump to continuously fill materials of varying viscosities. Vacuum filling, removing air during the filling process, is suitable for oxidation-sensitive products.

The filling nozzle is designed to minimize spillage and foaming. Many machines are equipped with anti-drip nozzles and volume adjustment controls to ensure that each bottle receives the exact amount required.

3) Capping Process in the Bottle Filling and Capping Machine

Once the bottle is filled, it moves to the next step in the production line.

- Bottle filling and capping machines use cap feeders or cap elevators to deliver caps to the correct position. A vibrating bowl feeder evenly arranges the caps. Sensors check for missing caps before the capping stage.

By automating cap handling, this process reduces manual labor and ensures that each bottle is capped quickly and correctly.

4) Capping Process in the Bottle Filling and Capping Machine

The capping stage involves placing the caps in the correct position. This step is crucial in the production line.

- Bottle filling and capping machines may use different capping methods: screw caps, commonly found on threaded plastic and metal caps; press caps, snap-on caps used on beverage bottles; and ROPP caps, roll-on tamper-evident caps, which provide a tamper-evident seal.

A torque control system ensures that each cap is tightened evenly, avoiding problems such as overtightening or loose seals.

5) Output and Quality Control in the Bottle Filling and Capping Machine

After capping, the bottles leave the bottle filling and capping machine and move along a conveyor for labeling or packaging. Many advanced systems include:

- Vision inspection to detect underfilled bottles or missing caps; Rejection mechanisms to automatically reject defective bottles; and Data tracking to record production quantities for quality management.

These features ensure that only properly filled and sealed products reach the market.

3. Understanding the working principles and applications of bottle filling and capping machines in various industries

- This allows for better equipment selection and choosing the right machine type for your product. Maintenance plans to keep the machine running at optimal performance. Operator training to effectively train employees for smoother operations.

- Bottle filling and capping machines can be used for: water, juice, soft drinks, and alcoholic beverages in the beverage industry; sauces, oils, and condiments in the food industry; lotions, creams, and essential oils in the cosmetics industry; and cleaning solutions and liquid detergents in the chemical industry.

- Each sector uses slightly different configurations to match product characteristics, but the operating principles remain similar.

Conclusion:

The working principle of a bottle filling and capping machine involves a seamless process of bottle loading, precise filling, automatic cap feeding, precise capping, and final output inspection. By integrating these steps into a single machine, manufacturers can increase productivity, improve product quality, and reduce production costs.

Whether you operate a small production facility or manage a large manufacturing plant, understanding how a filling and capping machine works will help you optimize its use. Investing in the right machine and knowing how to get the most out of it are key to maintaining a competitive advantage in today’s market.

0