Table of Contents

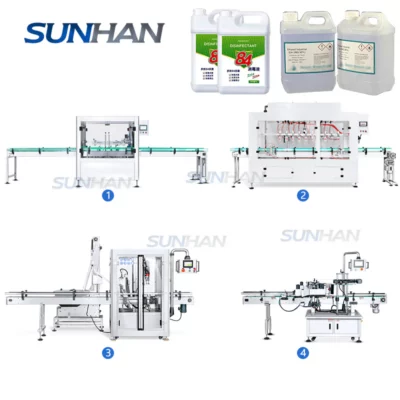

ToggleSUNHAN is a well-established packaging machine manufacturer specializing in custom-designed capping machines for various industrial sectors. With a strong focus on innovation, precision engineering, and tailored service, SUNHAN continuously enhances production efficiency and guarantees exceptional packaging quality.

Moreover, SUNHAN emphasizes adaptability, allowing its solutions to be customized for diverse customer requirements, reflecting its dedication to meeting unique operational challenges across global industries.

1. Company Overview

- Established Background

Founded in 2014 and based in Foshan, China, SUNHAN operates as Guangdong Shanghang Technology Limited. Recognized as a leading packaging machine manufacturer with expertise spanning filling, capping, labeling, and packaging machinery

- Global Reach and Reputation

Recognized as a reliable packaging machine manufacturer with expertise spanning filling, capping, labeling, and packaging machinery, SUNHAN exports its products to more than 30 countries across North America, Europe, and Asia. The company’s commitment to quality, innovation, and customer satisfaction has solidified its reputation as a trusted partner worldwide.

2. Technical Advantages of SUNHAN Customized Capping Machines

(1) Wide Cap Compatibility for Versatility

SUNHAN’s capping machines are highly versatile, compatible with a wide range of cap types such as screw caps, pump caps, flip-top caps, and spray caps.

This broad compatibility allows SUNHAN, as a leading packaging machine manufacturer, to serve industries including household products, chemical goods, and personal care items. Their machines allow for quick switching between cap types, significantly reducing downtime and increasing production line flexibility.

(2) Precise Torque Control for Quality Assurance

The torque control system of SUNHAN’s capping machines is adjustable between 5 and 30 Newton-meters (Nm), which enables precise control over tightening force, ensuring optimal sealing without damaging the container or contents.

(3) Seamless Integration and High-Speed Performance

Designed for seamless integration into existing production lines, these machines can operate at speeds up to 600 caps per minute.

The modular construction allows easy adaptation to different container sizes and shapes, reducing maintenance time and costs. This flexibility underscores SUNHAN’s customer-oriented approach as a packaging machine manufacturer.

3. Customer Support and Global Service

1) Comprehensive After-Sales Support

SUNHAN goes beyond equipment manufacturing by providing comprehensive after-sales services such as professional installation, operator training, and ongoing maintenance support.

2) Global Network and Technical Assistance

With a strong global support network, SUNHAN ensures prompt technical assistance that minimizes downtime and maximizes machine uptime. Their proactive use of remote diagnostics and regular software updates further enhances reliability, solidifying their reputation as a dependable packaging machine manufacturer.

4. Innovation and Sustainability

- Smart Technology Integration

SUNHAN continuously integrates smart technologies into its capping machines, including real-time torque monitoring, remote diagnostics, and predictive maintenance.

- Commitment to Eco-Friendly Packaging

Additionally, the company supports sustainable packaging initiatives by enabling machines to work with eco-friendly materials like biodegradable caps and recycled plastics. This commitment helps clients meet environmental regulations and growing market demands, reinforcing SUNHAN’s position as an innovative and responsible packaging machine manufacturer.

5. Conclusion

SUNHAN’s customized capping machines exemplify the company’s expertise and dedication as a premier packaging machine manufacturer. By combining advanced technology, adaptability, and excellent customer support, SUNHAN empowers clients to improve production efficiency, ensure packaging integrity, and maintain a competitive edge in evolving markets.

0